Why Do Carbon Brushes Matter in Modern Industry?

2025-09-18

Electric motors and generators are the foundation of modern industry, powering everything from household appliances to heavy industrial equipment. At the heart of many of these machines lies a small yet vital component: the carbon brush. Without it, motors would lose efficiency, suffer damage, or even fail to operate.

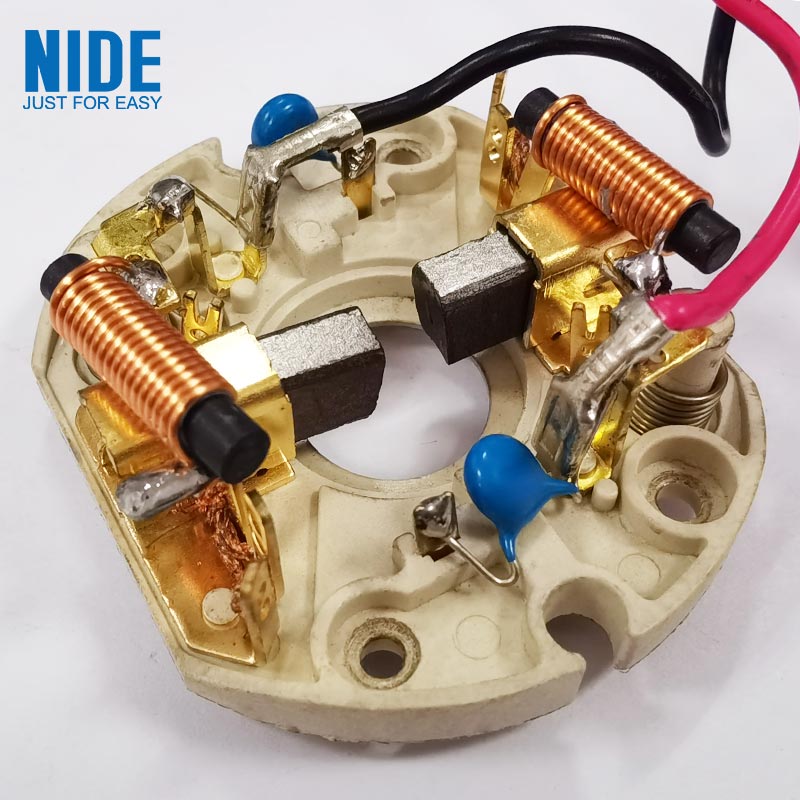

A carbon brush is a sliding electrical contact made primarily from graphite and other conductive materials. It transfers current between stationary wires and rotating parts, such as a commutator or slip ring. This seemingly simple component has an outsized role in ensuring smooth operation, reducing wear, and optimizing the performance of rotating electrical equipment.

The significance of carbon brushes can be summarized as follows:

-

Electrical Connectivity: They provide a stable connection between stationary and moving parts.

-

Durability: Graphite composition ensures wear resistance and self-lubricating properties.

-

Adaptability: Carbon brushes can be engineered to meet specific voltage, current, and environmental conditions.

-

Protection: By preventing arcing and excessive wear, they extend the life of motors and generators.

From small power tools to massive turbines, carbon brushes remain an indispensable part of electrical engineering.

What Functions Do Carbon Brushes Perform in Motors and Generators?

The working principle of a carbon brush is straightforward yet highly effective. It conducts electricity while simultaneously maintaining mechanical contact with a rotating element. However, the performance of a brush is influenced by its material composition, design, and operating conditions.

Core Functions of Carbon Brushes

-

Current Conduction

Carbon brushes carry electrical current from the external power source to the rotating commutator or slip ring. -

Commutation

In DC machines, they reverse current direction at the right moment to maintain continuous torque. -

Lubrication and Protection

Graphite acts as a lubricant, reducing friction between the brush and the commutator. This minimizes wear and extends motor lifespan. -

Spark Reduction

Properly designed brushes minimize sparking, which reduces energy loss and prevents damage to electrical contacts. -

Heat Dissipation

They help distribute and dissipate the heat generated by electrical resistance and mechanical friction.

Applications Across Industries

-

Automotive: Starter motors, alternators, and windshield wipers.

-

Household Appliances: Vacuum cleaners, washing machines, and power drills.

-

Industrial Equipment: Welding machines, elevators, pumps, and conveyors.

-

Energy Generation: Turbines, hydroelectric generators, and wind power systems.

-

Railway and Transportation: Traction motors for trains and electric vehicles.

Key Technical Parameters of Carbon Brushes

| Parameter | Specification Options / Range |

|---|---|

| Material Composition | Electrographite, resin-bonded graphite, copper graphite |

| Hardness | Shore D 35–100 depending on grade |

| Electrical Resistivity | 10–20 µΩ·m typical range |

| Current Density | 5–25 A/cm² depending on motor type |

| Operating Temperature | -40°C to 350°C (depending on grade) |

| Dimensions | Customizable based on motor design |

| Spring Pressure | 150–300 g/cm² typical load |

The ability to customize these parameters allows manufacturers to design carbon brushes for specific motor requirements, ensuring maximum performance and longevity.

What Factors Should Be Considered When Selecting the Right Carbon Brush?

Not all carbon brushes are created equal. The right choice depends on operating conditions, electrical requirements, and mechanical design. Using the wrong type can lead to premature wear, overheating, or motor failure.

Key Considerations for Selection

-

Material Type

-

Electrographite: Excellent wear resistance, used in high-load applications.

-

Copper Graphite: Higher conductivity, ideal for low-voltage and high-current systems.

-

Resin-Bonded Graphite: Softer, quieter, suitable for household appliances.

-

-

Motor Type

-

DC motors require brushes with precise commutation properties.

-

AC slip ring motors demand brushes with high thermal stability.

-

-

Operating Environment

-

In dusty or humid conditions, brushes should resist contamination.

-

For high-temperature environments, special high-grade carbon is necessary.

-

-

Load and Duty Cycle

-

Continuous heavy-duty motors need high-durability brushes.

-

Intermittent use equipment benefits from brushes optimized for start-stop conditions.

-

-

Maintenance Requirements

-

Easy-to-replace brushes reduce downtime.

-

Long-life brushes are cost-effective in high-production industries.

-

Advantages of Proper Carbon Brush Selection

-

Extended motor life.

-

Reduced downtime and maintenance costs.

-

Higher efficiency and power output.

-

Improved safety through minimized sparking.

Common FAQs About Carbon Brushes

Q1: What causes carbon brushes to wear out quickly?

A: Premature wear can result from poor material choice, excessive spring pressure, contaminated environments, or electrical overload. Selecting brushes with the right grade and maintaining clean commutators can significantly extend lifespan.

Q2: What is the recommended maintenance routine for carbon brushes?

A: Regular inspection of brush length, spring tension, and commutator surface is essential. Brushes should be replaced before reaching their minimum length. Cleaning commutators and checking for uneven wear prevents costly breakdowns.

What Is the Future of Carbon Brushes in a Changing Technological Landscape?

With the growing popularity of brushless motors in some industries, many question whether carbon brushes will continue to play a major role. The reality is that while brushless technologies are advancing, carbon brushes remain indispensable in countless applications due to their simplicity, reliability, and cost-effectiveness.

Emerging Trends in Carbon Brush Technology

-

Advanced Materials: Development of hybrid graphite composites for longer lifespan.

-

Sustainability: Use of eco-friendly materials and recycling initiatives for spent brushes.

-

Precision Engineering: Tailored solutions for specialized applications, from aerospace to renewable energy.

-

Smart Monitoring: Integration with sensors to track wear in real-time and predict replacement cycles.

Continued Relevance of Carbon Brushes

-

In heavy industries, carbon brushes offer rugged durability where electronic alternatives are not viable.

-

In household appliances, they remain cost-effective and easy to maintain.

-

In power generation and transportation, they ensure reliable performance under variable conditions.

As industries continue to demand dependable solutions, carbon brushes will adapt and evolve, rather than disappear. Their versatility ensures that they remain a cornerstone of motor and generator design.

At NIDE, we provide high-quality carbon brushes designed to meet the demanding needs of global industries. Our brushes are manufactured with precision, using advanced materials that ensure durability, electrical stability, and minimal maintenance. Whether you need carbon brushes for household appliances, industrial machinery, or power generation systems, our team can deliver solutions tailored to your exact requirements.

For inquiries, technical specifications, or customized carbon brush solutions, contact us today and discover how NIDE can support your business with reliable products and expert service.