Why Are Flange Bearings Critical for Industrial Machinery Performance?

In the world of mechanical engineering and industrial automation, flange bearings play a pivotal role in ensuring the smooth and efficient operation of rotating equipment. Whether used in conveyors, electric motors, agricultural machinery, or packaging lines, these specialized bearings support shafts and reduce friction under high loads and speeds.

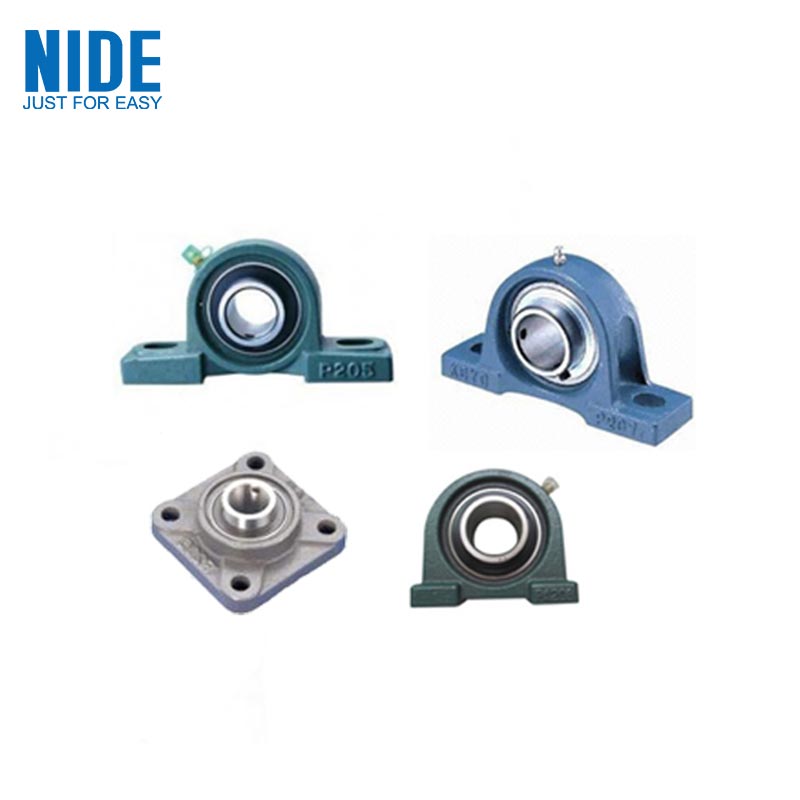

A flange bearing is a type of mounted bearing that is designed to support a rotating shaft while being fixed to a surface using a flange — a flat, projecting rim that provides additional stability. Unlike standard ball bearings, flange bearings come pre-mounted within a housing that can be easily attached to machinery structures.

The design ensures that alignment remains precise and that the shaft remains stable during operation. Typically, flange bearings are made with high-strength steel or cast iron housings, and they contain precision-engineered ball or roller elements to handle radial and axial loads efficiently.

Common Flange Bearing Types Include:

-

2-bolt flange bearings: Compact design suitable for light to medium-duty applications.

-

3-bolt flange bearings: Offers additional support and alignment for uneven load distribution.

-

4-bolt flange bearings: Designed for heavy-duty industrial environments with higher stability requirements.

Flange bearings are commonly found in conveyors, fans, pumps, agricultural equipment, and electric motors — essentially anywhere a rotating shaft needs to be supported with minimal vibration and friction.

How It Works:

Inside the housing, the bearing insert (typically a deep-groove ball bearing) allows the shaft to rotate freely. The flange mounting keeps the bearing aligned and stable, preventing shaft misalignment, which can otherwise lead to premature wear or mechanical failure.

The bearing may also include self-aligning features or set screw locking mechanisms that help secure the shaft under varying loads and operating conditions. This makes flange bearings both durable and easy to maintain, even in high-demand applications.

Why Are Flange Bearings Important in Industrial Applications?

The importance of flange bearings lies in their ability to enhance both mechanical efficiency and system longevity. By providing stable support for rotating components, they minimize friction, reduce energy loss, and protect equipment from excessive vibration and wear.

Key Advantages of Using Flange Bearings:

| Feature | Description | Benefit |

|---|---|---|

| High Load Capacity | Supports both radial and axial loads effectively. | Extends the lifespan of machinery. |

| Easy Mounting and Alignment | Pre-drilled flange holes allow quick installation. | Reduces assembly time and maintenance cost. |

| Corrosion Resistance | Available in stainless steel or coated variants. | Suitable for harsh or wet environments. |

| Vibration Reduction | Maintains precise shaft alignment under motion. | Prevents noise and mechanical imbalance. |

| Sealed Protection | Dust and moisture seals ensure cleaner operation. | Reduces contamination and bearing wear. |

Why Industries Depend on Flange Bearings:

-

Agriculture: For tractors, harvesting machines, and irrigation pumps where consistent torque and alignment are critical.

-

Manufacturing: In conveyor systems, robotic arms, and packaging lines requiring continuous rotation with minimal downtime.

-

HVAC Systems: To support fans and blowers that operate under high-speed rotation and continuous use.

-

Automotive and Transportation: In axle assemblies and transmission systems requiring durability and stability under heavy loads.

Without properly designed flange bearings, these systems would experience increased friction, overheating, and mechanical wear — ultimately leading to higher maintenance costs and operational inefficiencies.

How to Choose the Right Flange Bearing for Your Application

Selecting the right flange bearing depends on load type, environmental conditions, shaft size, and rotational speed. Understanding these parameters helps ensure the bearing can withstand operational stresses while maintaining consistent performance.

Key Selection Criteria:

-

Shaft Diameter: The inner bore must match the shaft size precisely to prevent slippage or misalignment.

-

Load Requirements: Consider both radial (perpendicular) and axial (parallel) loads. Heavy-duty machines often require larger or reinforced flange bearings.

-

Material Composition:

-

Cast Iron: High strength and ideal for industrial environments.

-

Stainless Steel: Corrosion-resistant, suitable for food processing or marine use.

-

Thermoplastic Housing: Lightweight and resistant to chemicals, ideal for hygiene-sensitive industries.

-

-

Sealing Type: Bearings may come with rubber or metal seals to protect against dust, water, and lubricant loss.

-

Mounting Configuration: Choose between 2-bolt, 3-bolt, or 4-bolt patterns based on load distribution and space availability.

-

Operating Speed and Temperature: Bearings designed for high-speed rotation often include heat-treated components and specialized lubricants to prevent frictional overheating.

Maintenance Tips for Long-Term Use:

-

Regular Lubrication: Use manufacturer-recommended grease to prevent metal-to-metal contact.

-

Alignment Checks: Periodically ensure the shaft and housing remain correctly aligned.

-

Seal Inspection: Replace seals showing signs of wear or leakage to maintain contamination-free operation.

-

Temperature Monitoring: Excessive heat can signal lubrication failure or bearing overload.

Proper maintenance can extend the life of a flange bearing by years, significantly reducing downtime and repair costs in industrial systems.

Frequently Asked Questions About Flange Bearings

Q1: What causes premature failure in flange bearings?

Premature failure typically results from misalignment, improper lubrication, contamination, or excessive load beyond the bearing’s rated capacity. Regular maintenance and proper installation can prevent these issues.

Q2: How often should flange bearings be lubricated?

Lubrication intervals depend on the operating environment and load conditions. In high-speed or high-temperature applications, weekly or monthly lubrication may be required. In cleaner, lighter-duty environments, lubrication every 3 to 6 months is often sufficient.

Building Reliable Systems with NIDE Flange Bearings

Flange bearings may appear small compared to the machines they serve, but their role in ensuring smooth, efficient, and safe operation cannot be overstated. From maintaining alignment to reducing vibration and energy loss, these components are vital for mechanical stability in a wide range of industries.

At NIDE, we manufacture precision-engineered flange bearings designed for long-lasting performance and low maintenance across various industrial applications. Our bearings combine advanced materials, accurate alignment technology, and robust sealing systems to ensure consistent operation even under harsh conditions.

If you are looking to improve your equipment’s efficiency or need assistance selecting the right flange bearing for your machinery, contact us today. Our technical team at NIDE is ready to help you choose the best solution for your application — ensuring durability, precision, and performance you can rely on.