How Does a Flange Bearing Improve Machinery Performance?

2025-10-21

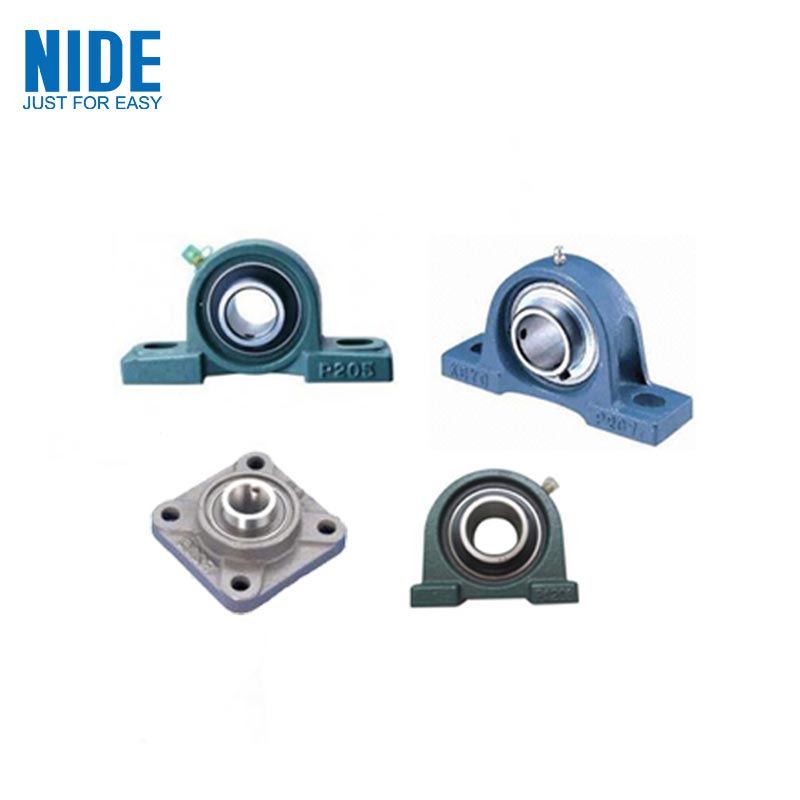

Flange bearings are specialized mechanical components designed to support rotating shafts while reducing friction between moving parts in industrial machinery. They are engineered to withstand significant loads, resist wear, and maintain precise alignment in mechanical systems. Unlike standard bearings, flange bearings incorporate a mounting flange that provides enhanced stability and simplifies installation in applications where axial support and positioning are critical.

What Are Flange Bearings and How Do They Differ From Standard Bearings?

Flange bearings are rolling-element bearings with a mounting flange attached directly to the bearing housing. This design facilitates secure and accurate mounting on machinery frames, eliminating misalignment and enhancing rotational stability. They are typically made from high-strength steel, stainless steel, or engineered polymers to provide durability under diverse operating conditions.

Key distinguishing features include:

-

Integrated Flange: Provides easy attachment to machinery frames without requiring additional mounting brackets.

-

Load Distribution: Optimized to handle both radial and axial loads, depending on the flange bearing design.

-

Alignment Accuracy: Maintains precise shaft alignment, which reduces wear on connected components and enhances operational efficiency.

-

Versatility: Suitable for various applications, including conveyor systems, agricultural machinery, automotive systems, and industrial equipment.

Detailed Technical Parameters of Flange Bearings:

| Parameter | Description |

|---|---|

| Bearing Type | Ball bearing, roller bearing, or sleeve bearing |

| Flange Material | Cast iron, stainless steel, or engineering plastics |

| Bore Diameter | Standardized from 12mm to 100mm (custom sizes available) |

| Outer Diameter | 32mm to 150mm |

| Flange Thickness | 5mm to 20mm |

| Load Capacity (Dynamic) | 5000 N – 50,000 N |

| Load Capacity (Static) | 6000 N – 60,000 N |

| Operating Temperature Range | -30°C to +150°C |

| Lubrication Method | Grease-lubricated, oil-lubricated, or self-lubricating |

| Mounting Options | Four-bolt flange, two-bolt flange, or square flange |

Flange bearings are engineered to balance load capacity, friction reduction, and ease of maintenance. Selecting the right type depends on application requirements such as load type, environmental conditions, and operational speed.

Why Are Flange Bearings Critical for Industrial Efficiency and Machine Longevity?

Industrial machinery is subject to continuous rotational motion, high load stress, and vibration. Improper bearing selection can lead to operational inefficiencies, equipment damage, and unplanned downtime. Flange bearings mitigate these risks by providing:

-

Reduced Friction: Minimizes energy loss and lowers operational costs.

-

Enhanced Load Support: Effectively manages radial and axial loads, preventing premature failure.

-

Precision Alignment: Maintains machinery alignment, reducing wear on shafts, gears, and pulleys.

-

Vibration and Noise Reduction: Supports smoother operations in high-speed or high-load applications.

-

Ease of Maintenance: Integrated flanges simplify installation and replacement without extensive machinery disassembly.

Industries increasingly rely on flange bearings due to their ability to improve machine performance, reduce downtime, and extend component life. For example, in automotive assembly lines, flange bearings maintain conveyor alignment under heavy loads, ensuring consistent product quality. In agricultural equipment, they withstand harsh environments, including exposure to dust, water, and fluctuating temperatures.

Why Choosing the Right Flange Bearing Matters:

Selecting a bearing that matches load requirements, environmental conditions, and operational speed is essential. Incorrect sizing or material selection can result in:

-

Premature bearing wear and failure

-

Increased energy consumption due to friction

-

Vibration-induced damage to connected machinery

-

Higher maintenance and replacement costs

By investing in precision-engineered flange bearings, industrial operators can achieve reliable, long-lasting performance across diverse machinery types.

How Do Flange Bearings Function and What Are Their Key Advantages?

Flange bearings function by providing a low-friction interface between a rotating shaft and stationary support. The rolling elements—balls or rollers—carry the load, while the flange ensures correct positioning and stability. Understanding their operational mechanics helps engineers optimize machinery performance and avoid common maintenance pitfalls.

Key Functional Principles:

-

Load Distribution: The bearing flange evenly distributes forces along the mounting surface, preventing localized stress concentrations.

-

Friction Reduction: Rolling elements minimize contact friction between the shaft and housing.

-

Rotational Stability: The flange prevents lateral movement, ensuring accurate shaft alignment and smooth rotation.

-

Maintenance Efficiency: Lubrication channels or self-lubricating materials reduce the frequency of maintenance interventions.

Primary Advantages of Flange Bearings:

-

Durability: Constructed from high-strength materials to withstand heavy-duty operations.

-

Versatility: Suitable for horizontal, vertical, and angled installations.

-

Operational Reliability: Reduces wear on adjacent machinery components.

-

Simplified Installation: The flange eliminates the need for complex mounting structures.

-

Cost Efficiency: Extended lifespan and reduced downtime lower overall operational costs.

Common Application Examples:

-

Conveyor belts in manufacturing plants

-

Agricultural machinery and harvesters

-

Automotive drive shafts and steering systems

-

Industrial fans, pumps, and compressors

Frequently Asked Questions (FAQs):

Q1: How often should flange bearings be lubricated in high-load applications?

A1: Lubrication frequency depends on operational speed, load, and environment. Typically, grease-lubricated bearings require inspection every 500–1000 operational hours. In dusty or wet environments, more frequent lubrication is recommended. Proper lubrication reduces friction, prevents overheating, and prolongs bearing life.

Q2: Can flange bearings be used in high-temperature applications?

A2: Yes, flange bearings made from high-grade stainless steel or heat-resistant polymers can operate in temperatures up to 150°C. It is crucial to select a bearing with appropriate seals and lubrication that withstands thermal expansion and prevents lubricant degradation.

Future Trends and Industrial Significance of Flange Bearings

The role of flange bearings in modern machinery continues to evolve as industries adopt automation, robotics, and high-speed production technologies. Future trends include:

-

Advanced Materials: Development of ceramic and composite bearings to reduce weight and increase heat resistance.

-

Smart Bearings: Integration of sensors for real-time monitoring of temperature, vibration, and load to enable predictive maintenance.

-

Sustainable Lubrication: Use of eco-friendly lubricants and self-lubricating materials to reduce environmental impact.

-

Enhanced Design Optimization: Precision engineering for high-speed, high-load, and high-vibration applications to improve efficiency.

Industrial operators increasingly prioritize flange bearings for machinery longevity, energy efficiency, and maintenance optimization. As manufacturing demands grow, flange bearings remain a reliable solution for reducing operational disruptions while supporting advanced mechanical systems.

Conclusion: Flange Bearings as a Cornerstone of Industrial Machinery

Flange bearings provide unmatched stability, precision, and durability in industrial machinery. By reducing friction, supporting complex loads, and facilitating accurate shaft alignment, they significantly enhance operational efficiency and prolong equipment lifespan. NIDE’s range of flange bearings combines high-strength materials, precise engineering, and innovative design to meet the most demanding industrial requirements. For more information or to select the ideal flange bearing for specific applications, contact us today.