Why Is a Washing Machine Motor Commutator Essential for Reliable Laundry Performance?

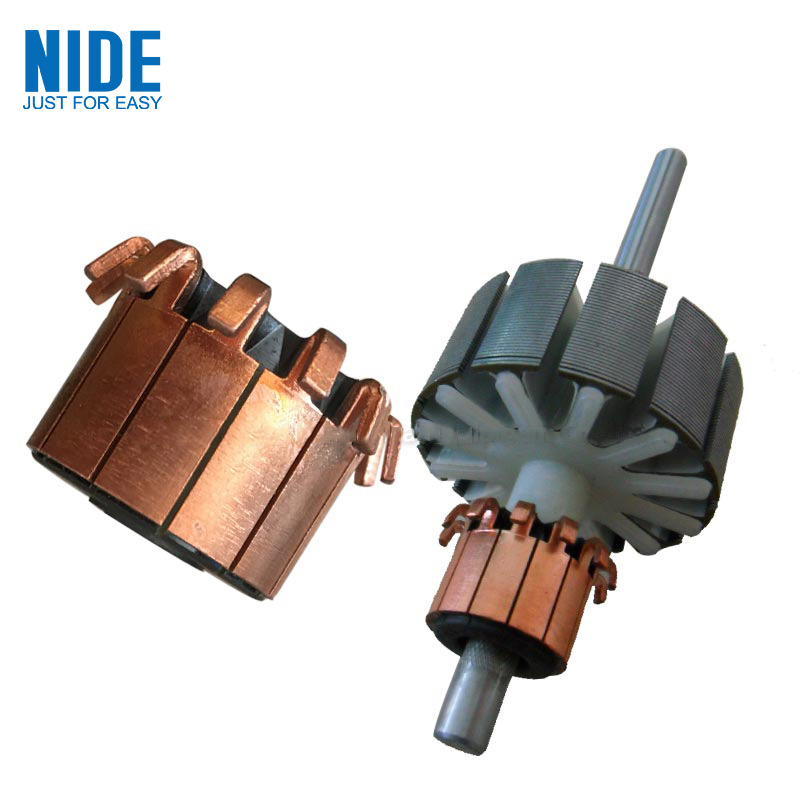

A Washing Machine Motor Commutator plays a vital role in ensuring stable power transmission and efficient drum rotation. As a core electrical component inside the motor, it directly affects washing performance, energy consumption, noise level, and service life. When I evaluate washing system components, I often ask whether the commutator design is optimized for torque, current stability, and durability. The answer always reveals the overall motor quality.

As a professional supplier, Ningbo Haishu Nide International Co., Ltd. provides high-precision commutators designed for long-term stability and strict performance requirements. In daily applications, I have witnessed how a well-built commutator significantly improves motor efficiency, reduces carbon brush wear, and enhances washing results.

What Key Features Define a High-Quality Washing Machine Motor Commutator?

A premium commutator must deliver smooth current switching, excellent concentricity, and heat resistance. The following technical features define the quality:

-

Stable electrical conductivity

-

Low resistance variation

-

High mechanical strength

-

Heat-resistant resin and copper materials

-

Long service life with reduced spark wear

-

Strict dimensional tolerance control

These features ensure consistent rotation speed and effective washing cycles.

How Do the Technical Parameters Enhance Washing Performance?

Below are the essential product parameters commonly used by Ningbo Haishu Nide International Co., Ltd.:

Product Parameter Table

| Parameter | Specification Range |

|---|---|

| Material | Copper + Resin / Silver Copper Options |

| Outer Diameter (OD) | 10–60 mm (customizable) |

| Inner Diameter (ID) | 3–20 mm |

| Number of Segments | 8–36 |

| Resistance | Low resistance, stable conduction |

| Working Temperature | 120–180°C |

| Application | Universal motors for washing machines |

| Custom Service | Structure, size, and segment customization |

Technical Advantages

-

High concentricity ensures stable rotation

-

Excellent thermal stability maintains long operational life

-

Optimized copper segments reduce electrical noise

-

Tight tolerance control improves motor efficiency

-

Custom manufacturing available for premium washing machine brands

Why Does a Washing Machine Motor Commutator Improve Operation Results?

The commutator influences how power is delivered to the rotor. When the Washing Machine Motor Commutator is engineered with precision, washing machines achieve:

-

Smoother drum rotation

-

Better torque output for heavy loads

-

Reduced vibration and noise

-

Improved washing and spinning efficiency

-

Lower heat generation

-

Extended lifespan of both motor and carbon brushes

When I replaced older models with updated designs, the operational improvement was immediately noticeable—greater torque consistency and quieter cycles.

How Important Is the Commutator in the Overall Washing Machine System?

The commutator is essential because it serves as the direct interface between electrical input and mechanical motion. Without a high-quality commutator:

-

Current switching becomes unstable

-

Motor efficiency decreases

-

Carbon brushes wear out faster

-

Torque output becomes irregular

-

Washing performance is compromised

This is why washing machine brands rely on manufacturers like Ningbo Haishu Nide International Co., Ltd. to supply commutators with precision manufacturing and strict quality control.

FAQ About Washing Machine Motor Commutator

Q1: What is the main function of a Washing Machine Motor Commutator?

A1: Its main function is to convert electrical energy into smooth mechanical rotation by switching current direction inside the motor. This ensures stable drum movement and optimized washing performance.

Q2: How long does a Washing Machine Motor Commutator typically last?

A2: A high-quality commutator can last several years, often matching the motor's lifespan, especially when made from durable copper segments and heat-resistant resin. Proper brush maintenance further extends service time.

Q3: What problems occur if the Washing Machine Motor Commutator is worn out?

A3: Users may experience reduced torque, unstable spinning, increased noise, overheating, or failure to start. These issues occur because electrical switching becomes inconsistent when the commutator surface is damaged.

Q4: Can I customize the Washing Machine Motor Commutator for my motor design?

A4: Yes. Manufacturers such as Ningbo Haishu Nide International Co., Ltd. offer customization for dimensions, materials, number of segments, and structure to match different motor specifications.

If you need high-precision components or custom specifications for your motor project, feel free to contact Ningbo Haishu Nide International Co., Ltd. for professional technical support and product services.