What Makes a High-Precision Linear Shaft Essential for Modern Motion Systems?

2025-12-05

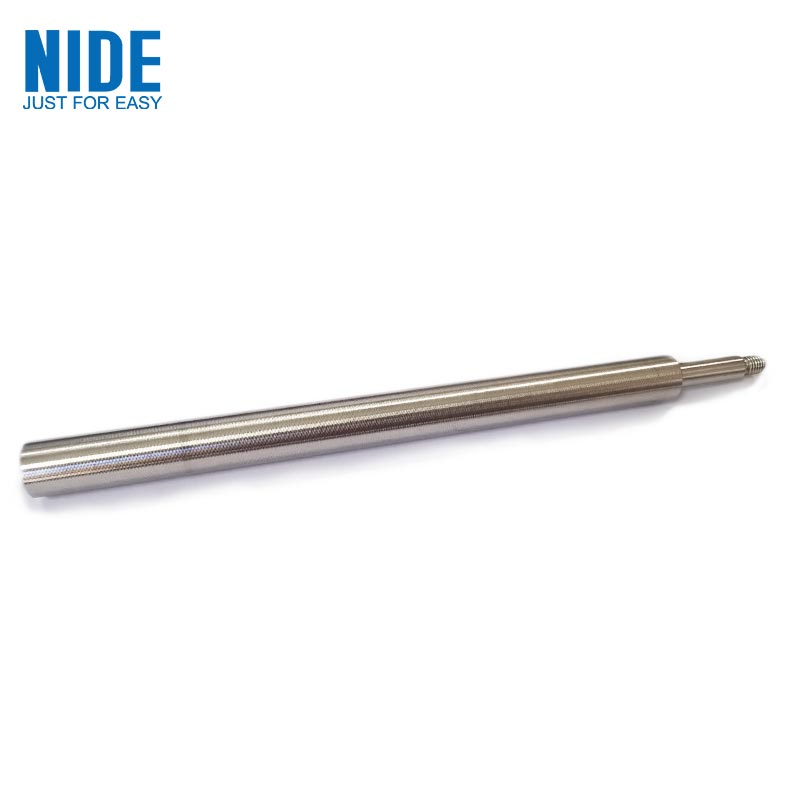

In today's automation-driven industries, the Linear Shaft has become one of the most important core components for guiding, supporting, and enabling smooth linear motion. From CNC machinery and packaging equipment to robotics, printers, and automotive production lines, its role directly affects equipment stability, service life, and overall accuracy. As a supplier with strong manufacturing capabilities, Ningbo Haishu Nide International Co., Ltd. provides Linear Shafts in multiple materials, surface hardness levels, tolerance grades, and customized lengths to match various industrial applications.

Why Choose a Linear Shaft for Precision Motion?

A Linear Shaft provides a stable, low-friction guide pathway that supports smooth motion and reduces vibration. Its precision-ground surface ensures tight dimensional consistency, which is critical in high-speed and high-accuracy environments.

Key Benefits

-

High rigidity and load-bearing capacity for automated or heavy-duty equipment

-

Superior surface finish to minimize friction and reduce wear

-

Long service life due to hardened and chrome-plated surfaces

-

Compatibility with linear bearings, ball bushings, and linear motion modules

How Do Different Materials Affect Linear Shaft Performance?

Choosing the right material is essential for environments such as high speed, high temperature, corrosive surroundings, or heavy loads. Below is the commonly used material comparison:

Typical Materials

-

Carbon Steel (e.g., 45# steel) – cost-effective, strong, ideal for general machinery

-

Stainless Steel (e.g., SUS304, SUS440C) – corrosion-resistant, suitable for humid, chemical, or food-grade environments

-

Alloy Steel (e.g., SUJ2) – excellent hardness and wear resistance, preferred for high-precision motion systems

What Are the Technical Specifications of Our Linear Shaft?

The following table summarizes the main parameters of our Linear Shaft products manufactured by Ningbo Haishu Nide International Co., Ltd.:

Linear Shaft Product Parameters

| Parameter Category | Specification Details |

|---|---|

| Diameter Range | 3 mm – 200 mm |

| Length Options | 100 mm – 6000 mm (customizable) |

| Material | Carbon Steel / Alloy Steel / Stainless Steel |

| Surface Hardness | HRC 58–62 (induction hardened) |

| Tolerance Grade | g6 / g5 / h6 (custom tolerance available) |

| Surface Roughness | Ra ≤ 0.4 µm |

| Plating/Coating | Chrome plated / Black oxide / Custom |

| Straightness | ≤ 0.03 mm per meter |

Which Applications Benefit the Most from a High-Quality Linear Shaft?

High-precision Linear Shafts are widely used in:

-

CNC machinery

-

Industrial robots

-

Packaging and printing devices

-

Medical and laboratory automation

-

Fitness equipment

-

Precision measuring tools

-

Electronics manufacturing systems

Industries with high demands for accuracy, smooth motion, and durability rely heavily on reliable Linear Shaft performance.

What Are the Performance Advantages of Our Linear Shaft?

1. Superior Stability

The hardened and precision-ground structure ensures that vibration and misalignment are minimized during operation.

2. Excellent Wear Resistance

Induction hardening combined with chrome plating reduces friction and extends lifespan even under continuous use.

3. High Accuracy and Consistency

The tight tolerance grade (g6 / h6) ensures smooth interaction with linear bearings.

4. Customizable Options

We support customization of length, material, coating, and machining options such as threading, keyways, and end-face processing.

5. Strong Industrial Compatibility

Our Linear Shafts can be paired with ball bushings, guide blocks, linear modules, and other motion components.

How to Choose the Right Linear Shaft for Your Equipment?

When selecting a Linear Shaft, consider the following guidelines:

-

Load requirements – heavier loads need larger diameters and stronger materials

-

Operating environment – corrosion-prone areas require stainless steel

-

Precision level – CNC and robotics need tighter tolerances

-

Speed and friction factors – high-speed movement requires smoother surfaces

-

Length and straightness – longer shafts must meet strict straightness requirements

Our engineering team at Ningbo Haishu Nide International Co., Ltd. can help custom match shafts to your machine's specifications.

FAQ About Linear Shaft

Q1: What is a Linear Shaft used for in automation systems?

A Linear Shaft guides linear bearings or blocks to achieve smooth, precise linear motion. It provides support, reduces friction, and ensures accuracy in automated machinery.

Q2: How long can a Linear Shaft be without losing straightness?

Most shafts maintain excellent straightness up to 6 meters when manufactured with proper hardening and grinding. For longer lengths, custom support structures or segmented designs may be used.

Q3: What factors determine the durability of a Linear Shaft?

Material quality, hardness level, surface treatment, and proper lubrication all significantly affect service life. Chrome-plated hardened shafts generally deliver the longest durability.

Q4: Can Linear Shafts be customized for special applications?

Yes. Diameter, length, threads, keyway slots, tapped holes, and special coatings can all be customized according to equipment designs.

Contact Us

For high-precision Linear Shaft solutions or custom manufacturing support, please contact Ningbo Haishu Nide International Co., Ltd. We provide professional engineering consultation, fast delivery, and reliable product quality for global customers.