How Does DM Insulation Paper Support High-Performance Electrical Applications?

2025-12-26

Abstract: DM Insulation Paper is a high-grade dielectric material widely used in transformers, motors, generators, and other electrical equipment. This article explores its composition, technical parameters, practical applications, and answers frequently asked questions for engineers and industry professionals. The focus is on understanding how DM Insulation Paper improves reliability, durability, and safety in electrical systems.

Table of Contents

- Introduction to DM Insulation Paper

- Technical Parameters of DM Insulation Paper

- Applications and Advantages in Electrical Equipment

- Frequently Asked Questions about DM Insulation Paper

- Brand Information and Contact

1. Introduction to DM Insulation Paper

DM Insulation Paper is a specialized electrical insulation material made primarily from high-quality cellulose fibers and treated with advanced impregnation resins. Its dielectric strength, thermal resistance, and flexibility make it a preferred choice in high-voltage and medium-voltage applications. The material is widely adopted across transformers, motors, generators, and other electrical devices where reliable insulation is critical.

The main objective of this article is to explain the key features, technical specifications, and practical applications of DM Insulation Paper while answering common technical questions to guide proper selection and usage.

2. Technical Parameters of DM Insulation Paper

The performance of DM Insulation Paper can be evaluated through its key technical parameters. Below is a detailed specification table illustrating professional-grade attributes:

| Parameter | Typical Value | Unit | Notes |

|---|---|---|---|

| Thickness | 0.05 - 0.5 | mm | Customizable according to insulation layer requirements |

| Dielectric Strength | ≥ 30 | kV/mm | High voltage resistance suitable for transformers and motors |

| Tensile Strength | ≥ 50 | MPa | Ensures mechanical durability under stress |

| Thermal Class | F (155°C) | °C | Can withstand high operational temperatures |

| Moisture Absorption | ≤ 2.5 | % | Minimizes degradation in humid environments |

| Insulation Resistance | ≥ 1000 | MΩ·cm | Maintains electrical insulation over long-term use |

3. Applications and Advantages in Electrical Equipment

3.1 Transformer Insulation

DM Insulation Paper is frequently used as interlayer insulation in transformers. Its high dielectric strength ensures safe voltage isolation between windings while maintaining minimal thickness, allowing for compact transformer design.

3.2 Motor and Generator Windings

In motors and generators, DM Insulation Paper provides critical insulation between coils and stator laminations. Its flexibility allows for easy wrapping, reducing installation time and ensuring long-term operational stability.

3.3 High-Voltage Equipment

DM Insulation Paper is suitable for high-voltage equipment, including circuit breakers and switchgears. The material's superior thermal and electrical properties improve safety and minimize downtime due to insulation failures.

4. Frequently Asked Questions about DM Insulation Paper

Q1: How is DM Insulation Paper manufactured to ensure high dielectric strength?

A1: DM Insulation Paper is manufactured using high-purity cellulose fibers that are processed under controlled moisture and temperature conditions. After forming the paper, it undergoes impregnation with resins such as phenolic or melamine to enhance dielectric strength and thermal stability.

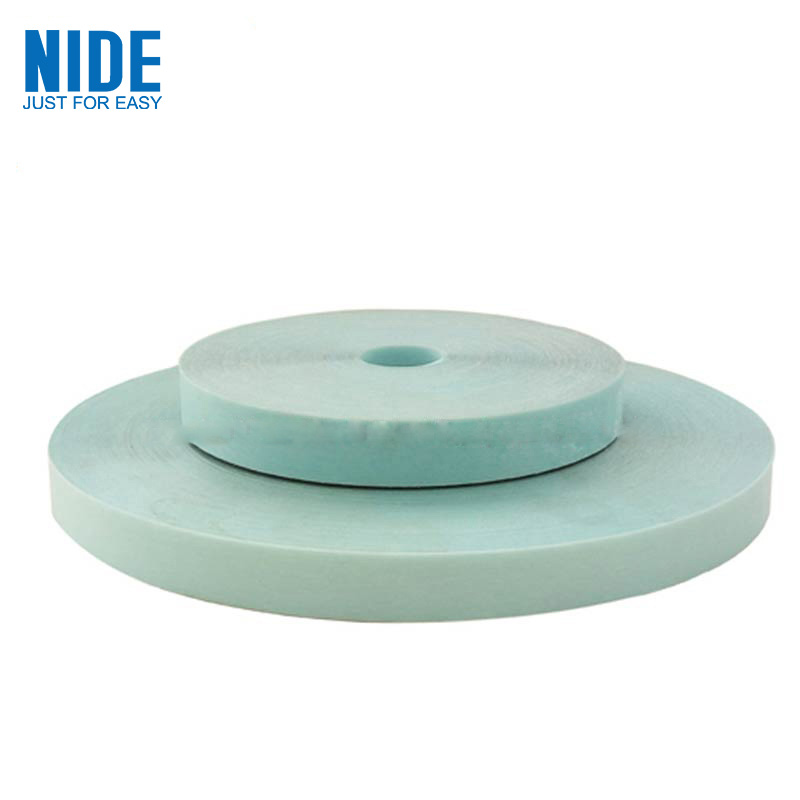

Q2: How should DM Insulation Paper be stored to maintain its properties?

A2: DM Insulation Paper should be stored in a dry, temperature-controlled environment, away from direct sunlight and moisture. Rolls should be kept horizontally or vertically in protective packaging to avoid compression and deformation that could reduce insulation performance.

Q3: How to select the right thickness and grade for a specific electrical application?

A3: The selection of DM Insulation Paper depends on operating voltage, temperature, and mechanical stress. For transformers, higher dielectric strength and thickness may be required for high-voltage windings. In motors, flexibility and thin layers are preferred for compact winding arrangements. Engineers should consult the technical datasheet and industry standards to determine the correct grade.

5. Brand Information and Contact

NIDE provides high-quality DM Insulation Paper designed to meet the demands of electrical equipment manufacturers globally. By maintaining rigorous quality control and using premium raw materials, NIDE ensures that each roll of DM Insulation Paper delivers consistent performance, reliability, and compliance with international standards.

For further inquiries, bulk orders, or technical consultation regarding DM Insulation Paper, please contact us directly. Our team is ready to provide professional guidance for your electrical insulation needs.